Decarbonizing the products we use every day by turning waste CO₂ into valuable molecules, powered by renewables

The world has begun to electrify its energy systems but not its molecules. Every battery, wind turbine, and solar panel still hides a paradox: about 80% of the materials that build our modern life like plastics, perfumes, coatings, medicines, explosives, come from fossil hydrocarbons. And above 90% of those molecules are imported into Europe.

This dependency isn’t just unsustainable. It’s a strategic weakness.

At ReMoléculaire, sustainability isn’t just a goal, it’s our essence. Our mission is to craft cutting-edge, high-performance molecules that power the shift from fossil dependence to circular chemistry. By transforming carbon dioxide into new value, we’re reimagining the foundation of industry and shaping a world where progress and the planet thrive together.

-

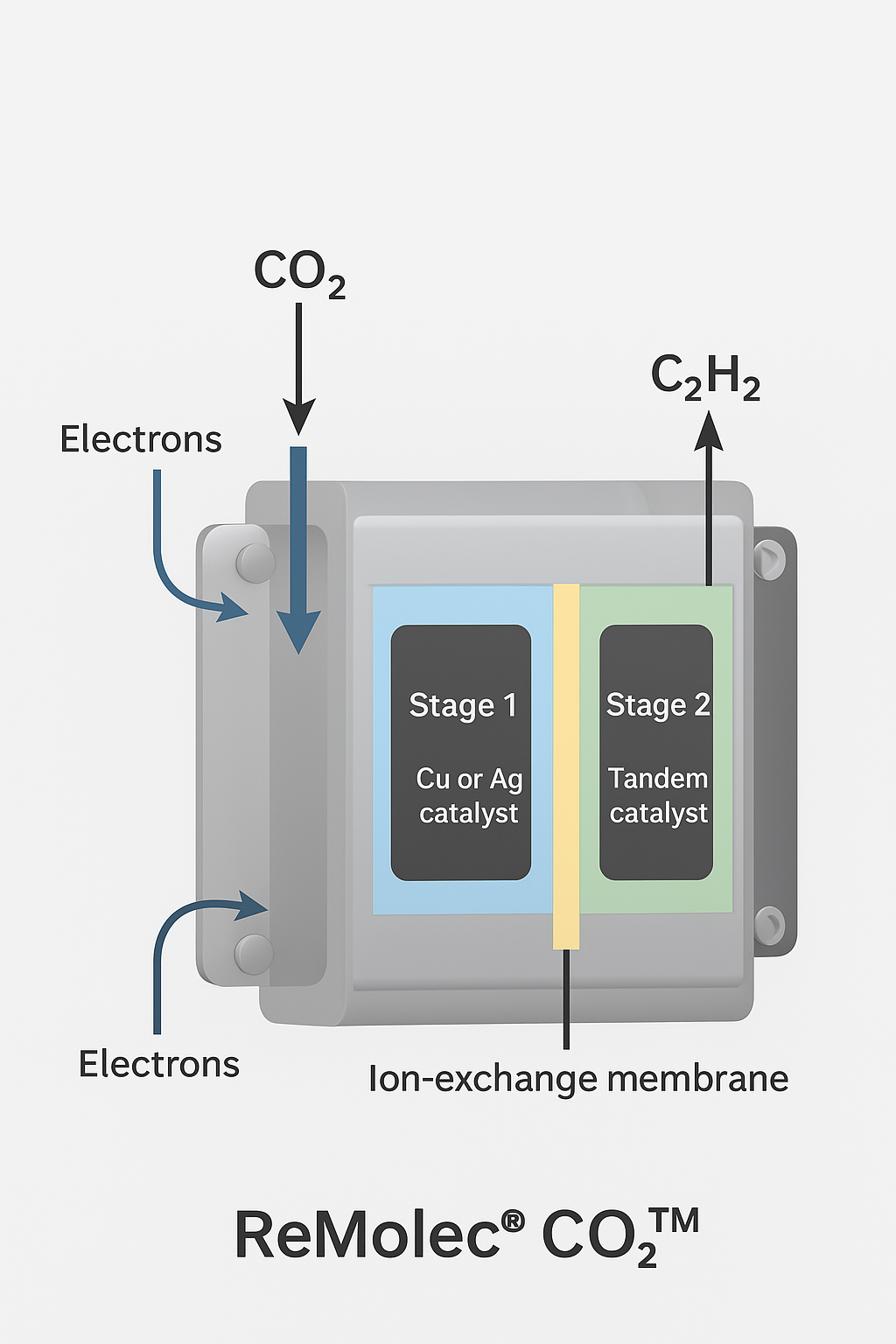

Our process uses renewable electricity and modular electrochemical reactors to convert CO₂ into acetylene (C₂H₂), a compact, energy-rich molecule that unlocks an entire universe of downstream chemistry.

Each ton of ReMoléculaire acetylene will prevent up to 4 tons of CO₂ emissions, while supplying industries that demand low-carbon building blocks -

ReMolec® TCA will run on renewable electricity and avoids the carbide production step. With a well-designed electrochemical process and renewable electricity.

Unlike single-step CO₂ conversion systems, TandemCO₂™ will have two catalytic zones to unlock C–C coupling and achieve high selectivity toward acetylene under mild, fully electrified conditions. -

1. Ultra-Low-Carbon BTX (Benzene, Toluene, Xylene)

CO₂-acetylene-to-aromatics route delivering <1 kg CO₂e/kg product.

Why it matters: First non-fossil, polymer-grade BTX — the cornerstone for polymers, coatings, and fine chemicals.2. Precision Para-Xylene for Low-Carbon PET/PTA

Highly selective p-xylene synthesis enabling monomer-level decarbonization for bottles, textiles, and films.

Edge: Delivers visible LCA wins and aligns with recycled-content regulations.3. Rocket-Grade Aromatics (C₇–C₉)

Ultra-stable, bio-inert aromatics engineered for propulsion fuels.

Edge: Certified fossil-free variant with unmatched purity and reliability.4. High-Flash, Low-Odor Solvents

Tailored acetylene-derived oxygenates for safer, cleaner coatings.

Edge: Combines superior film quality with ESG compliance.5. Conductive Polymer Precursors

Functionalized acetylene monomers for next-gen flexible electronics and battery materials.

Edge: High purity, consistent performance, and tunable conductivity.6. Fragrance-Grade Benzaldehyde & Phenylacetylenes

CO₂-derived aromatics identical in scent, superior in sustainability.

Edge: Premium margins through traceable, fossil-free storytelling.7. Medical-Grade Nitrile Monomers

Ultra-pure acrylonitrile and dinitriles for PPE and elastomers.

Edge: Secure, low-carbon supply for healthcare systems.8. Semiconductor & OLED Solvents

Electronics-grade aromatics and oxygenates meeting ppb impurity control.

Edge: High entry barriers and certification-driven customer loyalty.9. Isocyanate Precursors (Aniline → MDI/TDI)

CO₂-acetylene-to-aniline chain for sustainable foams and elastomers.

Edge: Deep decarbonization across construction and mobility sectors.10. Flame-Retardant Vinyls

Halogen-lite acetylene-derived monomers meeting advanced safety standards.

Edge: Regulatory advantage with sustainable chemistry.

Converting CO₂ into High-Value Chemicals and Materials

Electrochemical Alchemy

Our process uses electricity and waste CO₂ to make acetylene (C₂H₂), a compact, energy-dense molecule that serves as a clean building block for countless chemicals.

At the heart of the system is our electrochemical reactor, which uses renewable power to break down CO₂ and reassemble its carbon and oxygen atoms into new molecules. The process runs at ambient temperature and pressure, making it far safer and more efficient than traditional high-temperature fossil routes.

Each modular unit includes:

CO₂ preparation: The incoming CO₂ is cleaned and conditioned for the reaction.

Electrochemical cells: Inside, special catalysts and membranes drive the precise conversion of CO₂ into C₂ compounds like acetylene.

Product purification: The acetylene is then separated and refined to polymer-grade purity, ready for downstream use.

Energy recovery loop: Heat and gases are continuously recycled, minimizing waste and water use.

Because each reactor is containerized and modular, capacity can be expanded simply by adding more units. The result is a continuous, emission-free process that replaces fossil feedstocks with renewable carbon, redefining how the world produces its essential molecules.

-

Aromas & Essences

Crafting molecules that capture nature’s soul, engineered with industrial precision

Citral, the bright, lemon-like essence behind numerous fragrances and flavors, remains tied to fossil sources today. ReMoléculaire delivers a renewable breakthrough, producing citral directly from captured CO₂ powered entirely by clean electricity. -

BioPharma

Pharmaceutical chemistry demands uncompromising purity and traceability yet its core building blocks still come from fossil carbon and vulnerable supply chains. ReMoléculaire introduces acetylene as a clean, verifiable foundation for next-generation pharma precursors. Our next phase will deliver pilot quantities for validation into key intermediates like propargylamines and acetaldehyde derivatives.

-

Para-Xylene for Low-Carbon PET/PTA

Our high-selectivity para-xylene synthesis will redefine the building block for PET and PTA, the world’s most recycled polymer family.

By replacing fossil aromatics with CO₂, we will enable monomer-level decarbonization without changing existing infrastructure. -

Energetic Materials:

Toluene forms the cornerstone of defense-grade chemistry, serving as a critical precursor for TNT and a wide range of high-energy compounds.

We are on a mission to make fossil carbon obsolete.

We envision a world where every molecule, from perfume to polymer, originates from recycled CO₂. By uniting advanced electrochemistry with circular design, we aim to redefine the foundations of global chemical manufacturing and turn carbon from a liability into a limitless resource for a regenerative economy.

1. Molecule Sales

Direct supply of high-value, CO₂-derived molecules to sectors with urgent decarbonization needs (fragrances, defense materials, specialty polymers).

Drop-in compatibility with existing processes—no retooling—enables rapid fossil replacement.

Commercialization strategy

2. Platform Licensing

License our process for partners to run at their facilities with local integration.

Built for scale-oriented operators seeking clean-carbon capability and reduced dependence on fossil imports.

3. Molecule-as-a-Service

Containerized, point-of-use units operated by us; customers pay for delivered molecules.

Low-barrier, high-agility model for CO₂-rich, energy-aligned sites seeking climate performance without new infrastructure.

About Us

Farhan M. is a chemical process and energy engineer with cross-industry experience in sustainable process and product design, decarbonization strategy, life cycle assessment (LCA), and eco-innovation. His work bridges advanced process modeling, circular chemistry, and carbon conversion technologies — shaping the future of low-carbon manufacturing.

Previously at Sanofi and Veolia, Farhan led projects on solvent lifecycle optimization, low-carbon energy systems, and environmental impact modeling. Educated at École Polytechnique, KTH Royal Institute of Technology, and ESADE Business School, he combines deep technical expertise with strategic vision to accelerate the transition toward a circular, fossil-free chemical economy.

He is now channeling this experience into building ReMoléculaire, a next-generation carbon conversion venture transforming captured CO₂ into high-value molecular building blocks for industries that still depend on fossil hydrocarbons.

We are actively looking to collaborate with scientists, engineers, and business partners who share this vision.

If you’re ready to reimagine carbon — get in touch.

We’re seeking strategic partners and investors to collaborate to patent the process and accelerate pilot deployment and industrial integration.

Our goal is to incubate the project in France and scale it globally, starting with pilot partnerships in the French innovation ecosystem

Let’s build the carbon economy of the future.